Valve grinding is a crucial procedure in the maintenance and repair of internal combustion engines. This meticulous process ensures that engine valves seat properly, allowing for optimal engine performance. In this article, we will delve into the details of the valve grinding process, including its steps, tools used, benefits, and key considerations.

The Valve Grinding Process: Step by Step

Valve Removal

Before valve grinding can begin, the cylinder head must be removed from the engine. This allows access to the valves that need grinding.

Valve Inspection

Each valve is carefully inspected for wear, damage, and carbon buildup. Valves with excessive wear or damage may need replacement.

Valve Cleaning

The valves are cleaned to remove carbon deposits, oil, and dirt that can affect their seating and performance.

Valve Lapping

Lapping involves applying a lapping compound to the valve seat and using a specialized tool called a valve lapping stick. The valve is then rotated back and forth against the valve seat to create a smooth and precise mating surface.

Checking Valve Seat Contact

After lapping, the valve is placed back into its original position, and a special fluid is applied to the valve seat. The valve is then gently placed onto the seat, and its contact pattern is examined. This step ensures that the valve is making proper contact with the seat.

Final Inspection

Once the valve grinding process is complete, a final inspection is conducted to ensure that the valves are seating correctly and that there are no leaks.

Tools Used in Valve Grinding

Valve Lapping Stick

This tool is essential for the lapping process. It consists of a wooden or metal handle with a suction cup attached to one end. The lapping compound is applied to the valve seat, and the suction cup end is placed over the valve head for controlled lapping.

Valve Grinding Compound

Valve grinding compound, or lapping compound, is an abrasive paste used to create a smooth surface on the valve seat during lapping.

Valve Spring Compressor

This tool is used to compress the valve springs, allowing for the removal and installation of valves.

Benefits of Valve Grinding

Improved Sealing

Valve grinding ensures a proper seal between the valve and valve seat, preventing leakage of gases and improving engine compression.

Enhanced Performance

Properly ground valves optimize airflow and fuel mixture, leading to improved engine efficiency and power.

Extended Valve Lifespan

Valve grinding removes surface irregularities that can lead to premature wear, increasing the lifespan of the valves.

Key Considerations in Valve Grinding

Expertise

Valve grinding requires precision and skill. It's recommended to entrust this process to experienced professionals.

Valve Replacement

In some cases, valves with extensive damage or wear may need to be replaced rather than ground.

Proper Equipment

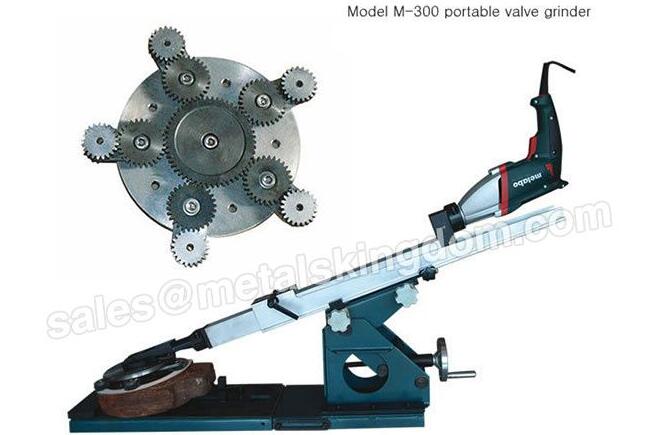

Using the right tools and equipment is essential for achieving accurate and consistent results.

Conclusion

The valve grinding process is a critical aspect of maintaining the performance and efficiency of internal combustion engines. By following the steps of valve removal, inspection, cleaning, lapping, and final inspection, engine valves can be properly seated for optimal engine operation. With the right valve grinding tools and expertise, valve grinding contributes to improved sealing, enhanced performance, and an extended valve lifespan, ensuring the smooth and efficient operation of the engine.

207

0

0

All Comments (0)

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments