In today's fast-paced world, efficient and cost-effective packaging solutions have become paramount for businesses across various industries. Stretch wrap films have emerged as a game-changer, offering versatile and reliable packaging options that cater to a multitude of needs. In this article, we will delve into the world of stretch wrap films, exploring their applications, benefits, and why they are an indispensable tool for modern packaging.

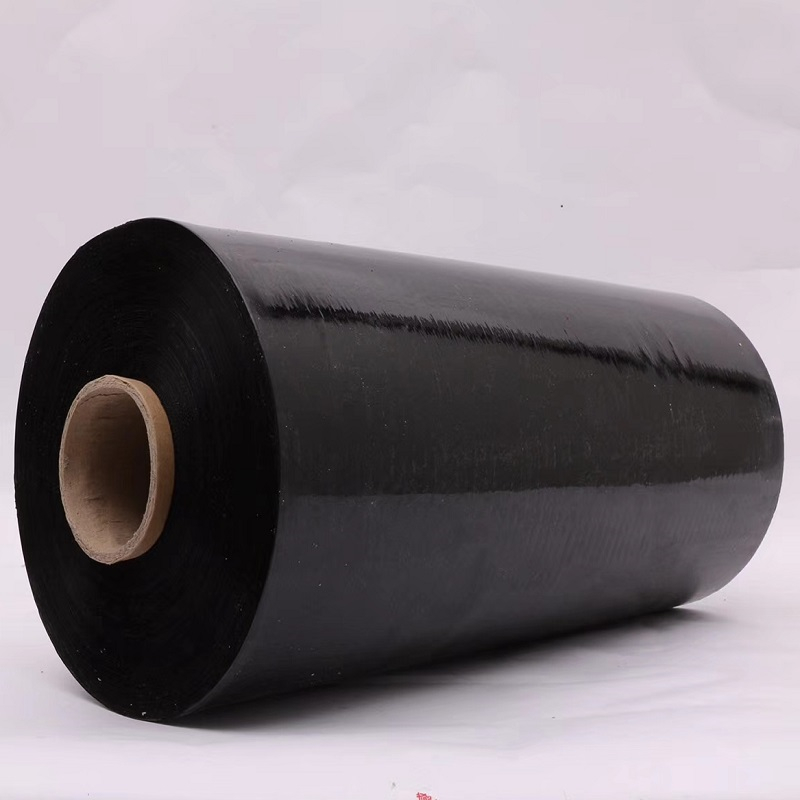

Stretch wrap films, also known as stretch film, pallet wrap, or shrink wrap, are thin, flexible sheets made from plastic materials, such as polyethylene. These films are designed to be stretched around products, boxes, or pallets, securing them tightly for storage, shipping, or display purposes. The stretchability of these films is their defining feature, allowing them to conform to various shapes and sizes with ease.

Cost-Efficiency: Stretch wrap films are cost-effective packaging solutions. They are significantly cheaper compared to alternatives like cardboard boxes or strapping materials, making them an economical choice for businesses of all sizes.

Protection: These films provide an additional layer of protection to goods. They shield products from dust, moisture, and other environmental factors, ensuring they reach their destination in pristine condition.

Versatility: Stretch wrap films are incredibly versatile. They can be used for bundling smaller items, securing palletized loads, or even wrapping irregularly shaped objects. Their adaptability is a significant advantage in diverse industries.

Visibility: Many stretch wrap films are transparent, allowing for easy identification of packaged items. This transparency aids in inventory management and reduces the need for frequent unwrapping and rewrapping.

Sustainability: In an era of increasing environmental awareness, some stretch wrap films are now available in eco-friendly variants. These biodegradable options cater to businesses looking to reduce their carbon footprint.

Stretch films find extensive use across a wide range of industries due to their versatility and effectiveness. Here are some notable applications:

In manufacturing units and warehouses, stretch wrap films are indispensable. They are used to secure palletized goods, preventing items from shifting during transit or storage. This not only reduces damage but also improves the efficiency of logistics operations.

In the food industry, stretch wrap films play a crucial role in preserving the freshness of perishable goods. They help create a barrier against contaminants and maintain the quality of food products during transportation.

Retailers use stretch wrap films for packaging and displaying products. The transparency of the film allows customers to see the product while keeping it protected and tamper-resistant.

In construction, these protection films are employed to bundle and secure construction materials, preventing them from scattering or becoming damaged on-site.

In conclusion, stretch wrap films have become an integral part of modern packaging solutions. Their cost-efficiency, versatility, and protective capabilities make them a valuable asset for businesses in various sectors. As industries continue to evolve, the demand for efficient packaging materials like stretch wrap films is expected to rise. Embracing these innovative solutions not only ensures the safety of goods but also contributes to streamlined logistics and reduced packaging costs. So, if you're in search of an effective packaging solution that ticks all the boxes, stretch wrap films are a choice worth considering.

249

0

0

All Comments (0)

Previous: How do you make a successful sticker?

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments