Feb. 12, 2025

Currently, there are four main processing methods for diamond: thin film coated tools, thick film diamond welding tools, diamond sintered body tools and single crystal diamond tools.

Thin film coated tools

Thin film coated tools are tools made by depositing diamond thin films on a collective material with good rigidity and high temperature characteristics through chemical vapor deposition (CVD).

Since the thermal expansion coefficients of Si3N4 ceramics, WC-Co cemented carbides and metal W are close to those of diamond, the thermal stress generated during film formation is small, so they can be used as the base material of the tool body. In WC-Co cemented carbides, the presence of the bonding phase Co easily forms graphite between the diamond film and the substrate, reducing the adhesion strength. Pretreatment is required before deposition to eliminate the influence of Co (generally, Co is removed by acid corrosion).

The chemical vapor deposition method uses a certain method to activate the gas containing the C source, and at an extremely low gas pressure, carbon atoms are deposited in a certain area. The carbon atoms form a diamond phase during the condensation and deposition process. The CVD methods currently used to deposit diamonds mainly include: microwave, hot filament, DC arc jet method, etc.

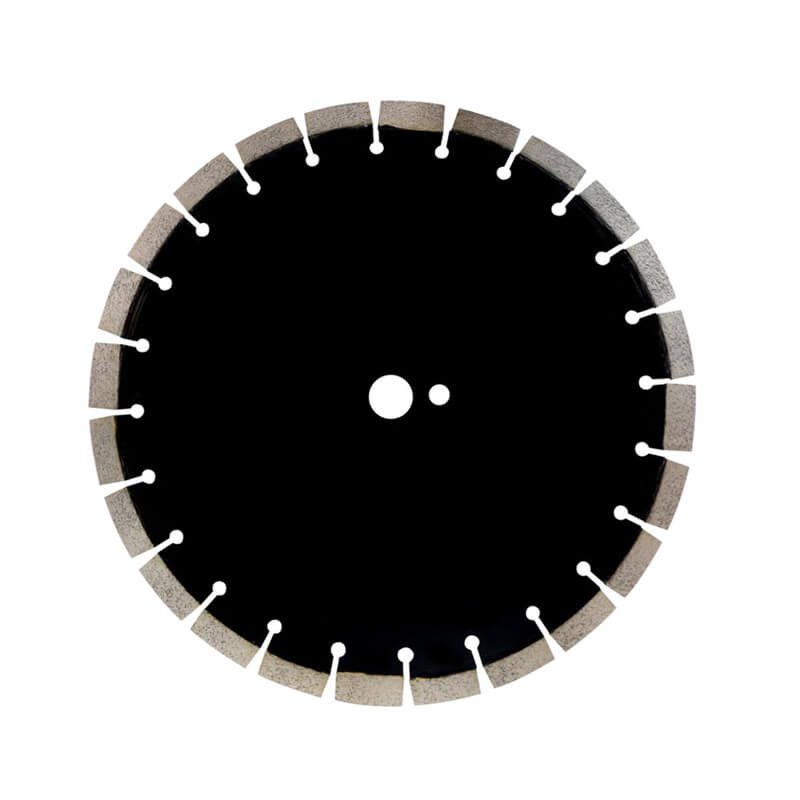

The advantage of diamond film is that it can be applied to various tools with complex geometric shapes, such as diamond blades with chips, end mills, reamers and drill bits; it can be used to cut many non-metallic materials, with small cutting force, small deformation, stable operation, slow wear, and the workpiece is not easy to deform. It is suitable for fine processing of workpieces with good material and small tolerance. The main disadvantage is that the adhesion between the diamond film and the substrate is poor, and the diamond film tool is not re-sharpenable.

Diamond thick film welding tool

The production process of diamond thick film welding tool generally includes: preparation of large area diamond film; cutting the diamond film into the shape and size required by the tool; welding the diamond thick film and the tool substrate material; grinding and polishing the cutting edge of the diamond thick film tool. (1) Preparation and cutting of diamond thick film

The commonly used process for preparing diamond thick film is DC plasma jet CVD method. Diamond is deposited onto WC-Co alloy (with mirror finish on the surface). During the cooling process of the substrate, the diamond film automatically falls off. This method has a fast deposition speed (up to 930μm/h), and the lattices are tightly bonded, but the growth surface is relatively rough. The high hardness, wear resistance, and non-conductivity of the diamond film determine that its cutting method is laser cutting (cutting can be carried out in air, oxygen, and argon environments). Laser cutting can not only cut the diamond thick film into the required shape and size, but also cut out the back angle of the tool, with the advantages of narrow cutting seam and high efficiency.

(1) Welding of diamond thick film tools

Diamond has a high interface energy with general metals and their alloys, which makes diamond unable to be wetted by general low-melting point alloys, and the weldability is extremely poor. At present, the weldability between diamond and metal is mainly improved by adding strong carbide-forming elements to copper-silver alloy solder or by metallizing the diamond surface.

① Active solder method

The solder is generally made of copper-silver alloy containing Ti, and is welded in an inert gas or vacuum without adding flux. The commonly used solder composition is Ag=68.8wt%, Cu=26.7wt%, and Ti=4.5wt%. The commonly used preparation methods are arc melting and powder metallurgy. Ti, as an active element, reacts with C to form TiC during the welding process, which can improve the wettability and bonding strength between diamond and solder. The heating temperature is generally 850℃, kept warm for 10 minutes, and slowly cooled to reduce internal stress.

② Surface metallization after welding

The metallization of the diamond surface is to plate metal on the diamond surface through surface treatment technology, so that the surface has metal or metal-like properties. Generally, Ti is plated on the surface of the diamond, and Ti reacts with C to form TiC. TiC has good wettability and bonding strength with Ag-Cu alloy solder. The commonly used titanium plating methods at present are: vacuum physical vapor deposition (PVD, mainly including vacuum evaporation plating, vacuum sputtering plating, vacuum ion plating, etc.), chemical vapor plating and powder covering sintering. The PVD method has a low single-time coating amount. The temperature of the diamond during the coating process is lower than 500°C. The coating and the diamond are physically attached and there is no chemical metallurgy. In the CVD method, Ti reacts chemically with diamond to form a strong metallurgical bond. The reaction temperature is high and damages the diamond.

(2) Sharpening of thick film diamond tools

The processing methods of thick film diamond tools include: mechanical grinding, hot metal disk grinding, ion beam, laser beam and plasma etching.

Diamond sintered body tools

The diamond thick film is processed into diamond grains with an average particle size of 32 to 37μm by rolling grinding or directly produced by high temperature and high pressure. The grain powder is piled on WC-16wt%Co alloy, and then isolated with Ta foil. It is sintered at 5.5GPa and 1500°C for 60 minutes to form a diamond sintered body. The turning tool made of this sintered body has high wear resistance.

Single crystal diamond tool

Single crystal diamond tool usually fixes the diamond single crystal on the small cutter head, and the small cutter head is fixed on the turning tool arbor with screws or pressure plates. The main methods of fixing the diamond on the small cutter head are: mechanical reinforcement method (grinding the bottom surface and pressure surface of the diamond flat, and fixing it on the small cutter head with pressure plate); powder metallurgy method (placing diamond in alloy powder, sintering it in vacuum under pressure, so that the diamond is fixed on the small cutter head); bonding and brazing method (using inorganic adhesive or other adhesive to fix diamond). Due to the huge difference in thermal expansion coefficient between diamond and substrate, diamond is easy to loosen and fall off.

6

0

0

All Comments (0)

Previous: None

Next: What is the Requirement for Refilling Fire Extinguishers?

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments