Mar. 13, 2025

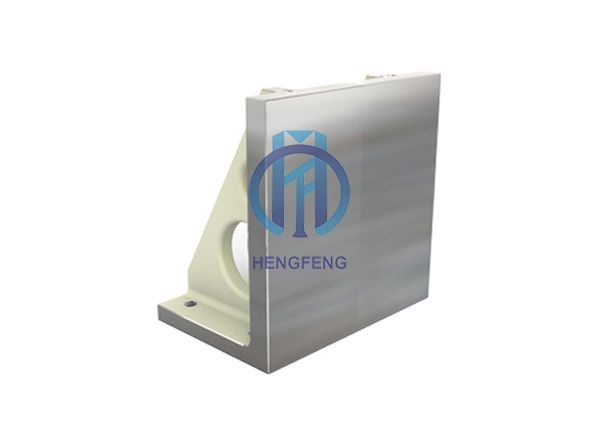

In machining, achieving perfect accuracy is crucial for producing high-quality components. A Precision Angle Plate is a key tool that helps machinists hold workpieces at precise angles for milling, drilling, grinding, and inspection. By ensuring stability and alignment, this tool minimizes errors and enhances machining efficiency.

Before using a Precision Angle Plate, choose the appropriate type based on your machining needs. Consider factors such as material, size, weight capacity, and flatness tolerance. High-quality plates made from hardened steel or cast iron offer better durability and accuracy.

To ensure stability, properly mount the Precision Angle Plate onto the machine table. Use clamps or bolts to prevent movement during machining. A stable setup reduces vibrations and enhances precision.

Place the workpiece against the Angle Plate to achieve the desired angle. Use gauge blocks, dial indicators, or precision measuring tools to verify the alignment before starting the machining process.

Once the workpiece is properly positioned, secure it using clamps or vices. Ensure that the clamping force is evenly distributed to prevent misalignment or deformation.

Before machining, double-check the setup using a surface gauge or digital angle finder. Precision is essential, especially for applications requiring tight tolerances, such as aerospace or automotive manufacturing.

With the workpiece properly secured and aligned, proceed with milling, drilling, or grinding. A well-positioned Precision Angle Plate ensures consistent and accurate results.

After machining, inspect the workpiece for accuracy. Use precision measurement tools like calipers, micrometers, or coordinate measuring machines (CMM) to verify the final dimensions and ensure they meet specifications.

Use a precision surface plate to verify the flatness of the Precision Angle Plate before setup.

Regularly clean and maintain the plate to prevent dust and debris from affecting accuracy.

Choose high-precision clamping tools to minimize setup errors.

Use dial indicators or laser measurement tools to confirm angle accuracy before machining.

A Precision Angle Plate is a vital tool for achieving perfect machining accuracy. By selecting the right plate, securing it properly, and following precise setup procedures, machinists can ensure consistent and high-quality results. Regular inspection and maintenance further enhance its effectiveness.

Have you used a Precision Angle Plate in your machining projects? Share your experiences or ask any questions in the comments below!

15

0

0

All Comments (0)

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments