Whether a carbide blade or a diamond blade is better for a particular cutting task depends on the material you are cutting and the specific requirements of your project. Each type of blade has its own advantages and limitations:

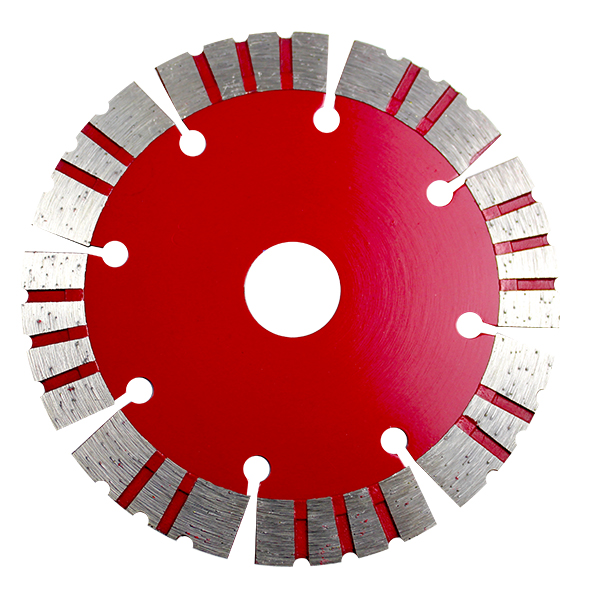

Diamond Blade:

Advantages:

Hardness: Diamond blades are incredibly hard and can cut through very hard materials, including concrete, stone, asphalt, and reinforced concrete.

Durability: They have a longer lifespan compared to carbide blades when used on hard materials.

Precision: Diamond blades can provide precise and smooth cuts, making them suitable for applications like decorative concrete.

Speed: They generally cut faster than carbide blades in hard materials.

Limitations:

Cost: Diamond blades are typically more expensive than carbide blades.

Not Ideal for All Materials: They may not perform well on softer materials, such as wood or plastic, as they are designed for hard materials.

Carbide Blade:

Advantages:

Versatility: Carbide blades can cut a wide range of materials, including wood, metal, plastic, and softer stones.

Cost: They are generally more cost-effective than diamond blades.

Longevity: Carbide blades can have a long lifespan when used on materials they are suited for.

Limitations:

Hardness Limitation: Carbide blades are not suitable for cutting extremely hard materials like concrete or stone. They will quickly wear out on such surfaces.

Precision: They may not provide the same level of precision and smoothness as diamond blades, especially on hard materials.

In summary, the choice between a carbide blade and a diamond blade depends on your specific cutting needs:

If you primarily need to cut hard materials like concrete, stone, or asphalt, a diamond blade is the better choice due to its hardness, precision, and durability in such applications.

If your cutting tasks involve a variety of materials, including wood, plastic, or softer metals, and you want a more cost-effective option, a carbide blade may be the better choice. However, it's important to note that carbide blades are not suitable for cutting extremely hard materials.

Ultimately, selecting the right blade comes down to matching the blade's characteristics to the material you need to cut and the quality and precision required for your project.

264

0

0

All Comments (0)

Previous: Applications of Galvanized Steel Wire Rope in Construction and Rigging

Next: What are the safety rules for diagonal cutting pliers?

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments