Jun. 18, 2024

Choosing the right bench vise is essential for a variety of woodworking, metalworking, and general DIY projects. Here are four key factors to consider when selecting a bench vise:

There are various types of bench vises available, each designed for specific tasks. The common types include:

Woodworking Vise: Designed for woodworking tasks, these vises typically have wooden jaws that are gentle on woodworkpieces. They come in various styles, such as front vises, tail vises, and face vises.

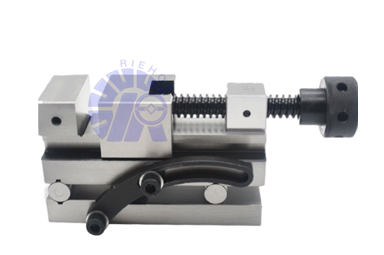

Mechanic's Vise: These are versatile and suitable for general-purpose tasks, including metalworking, assembly, and clamping. They often feature steel jaws with serrated or grooved surfaces for a secure grip.

Pipe Vise: Specifically designed for holding pipes, these vises have jaws with a V-shaped groove to grip pipes securely. They are commonly used by plumbers and metalworkers.

Consider the size and capacity of the vise. Bench vises are available in various jaw widths and opening capacities. Choose a vise that can accommodate the size of the workpieces you typically handle. For example, if you frequently work with larger materials, you'll need a vise with wider jaws and a higher clamping capacity.

Related links:The material and design of the vise jaws are crucial for grip, durability, and protection of your workpieces. Common materials for vise jaws include:

Steel: Steel jaws are sturdy and suitable for heavy-duty tasks but may mar or damage softer materials. Some steel jaws have serrations or grooves for better grip.

Wood: Wooden jaws are gentle on delicate workpieces and are often used in woodworking vises. They can be replaced or customized as needed.

Rubber or Nylon Inserts: Some vises come with replaceable rubber or nylon jaw inserts that provide a non-marring grip on sensitive materials.

Consider how the vise will be mounted on your workbench. Some vises have built-in mounting options, while others require additional hardware for installation. Ensure that the vise can be securely attached to your workbench to prevent wobbling or instability during use. Additionally, check if the vise has swiveling or rotating capabilities, which can be useful for positioning workpieces at different angles.

Remember to also factor in your specific needs and the types of projects you regularly undertake. While a versatile mechanic's vise may be suitable for general purposes, dedicated vises like woodworking or pipe vises offer specialized features that can enhance your workflow and project outcomes.

Related links:125

0

0

All Comments (0)

Previous: None

Next: Unveiling the Mastery of CNC Cylindrical Grinding: Crafting Precision with Innovation

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments